This chapter provides guidance in relation to noise, and is

primarily based on New Zealand legislation and guidance

issued by WorkSafe NZ.

All workers who undertake tasks where they are, or could be, exposed to excessive noise should read and understand the section on ‘minimum responsibilities’.

Roles that have specific responsibilities, or influence, over workers who are, or could be, exposed to excessive noise should read the section on ‘planning and guidance considerations and responsibilities’ – this includes producers, directors, production managers, line producers, heads of departments, assistant directors and health and safety officers.

Excessive noise, both short but extremely loud noise (impulse noise) and prolonged continuous noise, can cause noise induced hearing loss.

Exposure to excessive noise can also trigger workplace stress, causing anxiety or psychological harm, as well as headaches, fatigue and decreased concentration, increasing the risk of accidents. Excessive noise and noisy processes are also often associated with vibrations, which can impact a worker’s health.

Excessive noise exposure can also prevent people from hearing alarms or warning signals, limiting awareness and potentially leading to avoidable accidents.

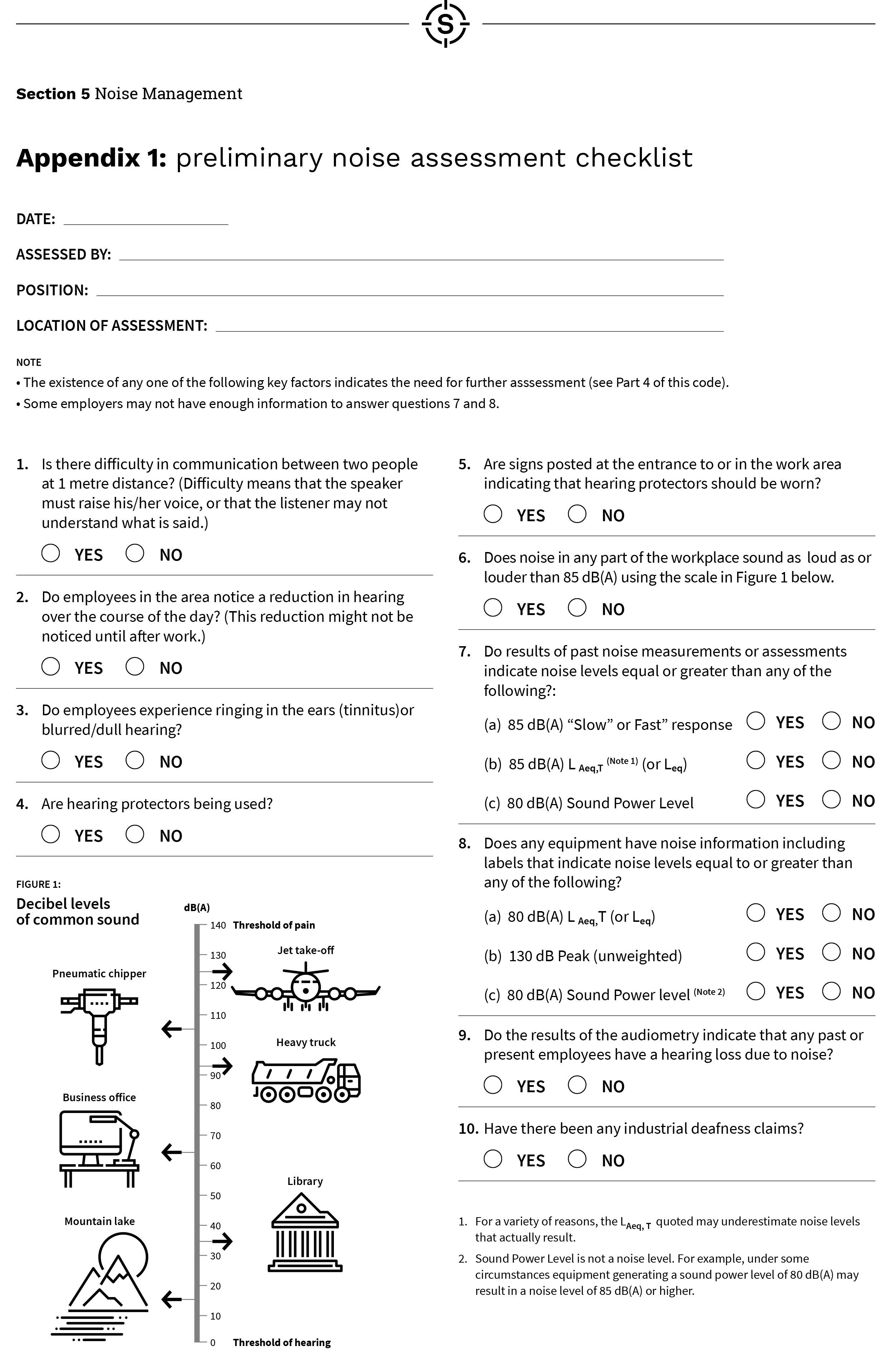

Daily exposure to noise above 85 decibels (dBA) will damage hearing; however, 85dBA might not mean a lot to most people.

Excessive noise, or a noise hazard, probably exists if:

Example of noise levels are outlined below

| SOUND LEVEL (dBA) | EXAMPLE OF NOISE SOURCE | EFFECT ON HEARING |

| 150 | Explosion | Instantaneous damage |

| 140 | Rifle shot | Damage over a brief period |

| 130 | Jet taking of | Threshold of pain |

| 120 | Power or chain saw | Damage after approx. 30sec |

| 110 | ||

| 100 | Pneumatic drill / Grinding metal / Noisy lawn mower | Some damage after approx. 15min |

| 90 | Heavy truck | Damage after two hours |

| 80 | Industrial sewing machine | DAt 85 dBA and below, an 8-hour day may be worked without using hearing protection devices |

| 70 | Street traffic |

Everyone who undertakes tasks where they are, or could be, exposed to excessive noise should read and understand this section, as well as the section on ‘what we need to know about noise’.

Anyone who is responsible for, or has influence over, workers who are, or could be, exposed to excessive noise should also read and understand the following section on ‘planning and guidance considerations and responsibilities’

All workers should:

Anyone who is responsible for, or has influence over, workers who are, or could be, exposed to excessive noise should also read and understand this section, as well as the minimum responsibilities for everyone.

This includes the production company, producers, directors, line producers, heads of departments, assistant directors and health and safety officers, who must consult, cooperate and coordinate with other PBCUs whose work may create, or be impacted by, excessive noise.

Everyone who is responsible for, or has influence over, an activity or task which creates, or is impacted by, excessive noise should:

Everyone who is responsible for an activity or task in relation to the production should consider the risks associated with excessive noise.

PRELIMINARY NOISE ASSESSMENT

A preliminary noise assessment is often called a walkthrough survey. It is a screening tool, which will help identify probable or possible excessive noise and should highlight which tasks, processes or areas in the workplace require a detailed noise assessment.

Anyone can undertake a preliminary noise assessment – see appendix A for an example of a checklist.

If you have to raise your voice to be heard, a detailed noise assessment should be undertaken.

DETAILED NOISE ASSESSMENT

A detailed noise assessment will determine if the workplace contains noise that exceeds the exposure limits, and is required when:

A detailed noise assessment must be undertaken by a competent person. Further information can be found in Management of noise in the workplace – Approved Code of Practice (ACOP).

As soon as a PCBU is aware that workers are being exposed to noise that exceeds exposure limits, they must put in place a hearing conservation programme2, which includes determining if hearing protection devices and hearing protection areas are required.

For more information about what needs to be considered as part of a hearing conservation programme refer to the Noise in the workplace – Approved Code of Practice (ACOP).

HEARING PROTECTION AREAS

Hearing protection areas are workspaces that have, or may have, excessive noise, where hearing protection devices must be worn, even if a worker or visitor is only in the area for a short amount of time.

These areas must be identified, with the areas and machinery concerned clearly labelled. The PCBU may wish to put up signs.

If signs are not practicable, the PBCU must work with workers to come up with other ways of informing both workers and visitors on set that they must wear hearing protection devices. This could include:

The requirements for hearing protector areas are detailed in clause 10 Hearing protector areas of AS/NZ 1269.

Elimination is the most effective control method; you do this by completely removing or avoiding the possibility that someone will be exposed to excessive noise – 85dBA a day or a peak sound pressure level, Lpeak, of 140 dB.

If complete elimination is not reasonably practicable, you must consider ways to minimise the risk so workers are not exposed to excessive noise.

There are two primary ways to minimise, or control, excessive noise – at the source or by isolating either the source or the worker.

You can control the source of the noise by:

Controlling noise at the source is best achieved at the planning stage; you can do this by:

If you cannot reduce noise exposure to less than 85dBA a day, the final option is to minimise the risk using suitable hearing protection

Controls that rely on human behaviour and supervision, such as personal protective equipment, must be the last controls considered as they provide the least protection and reliability.

If you cannot reduce the noise to a safe level for workers, you must ensure workers have suitable hearing protection devices (HPDs); the worker is responsible for using them appropriately.

Areas where HPDs must be worn must be designated hearing protection areas and, where practicable, signposted indicating that HPDs must be used.

The main types of HPDs are ear muffs and earplugs; either type can provide effective protection provided it makes an airtight seal in (plugs) or around (muffs) your ear.

The head of department, or equivalent supervisor:

It is important that hearing protectors fit correctly. For more information about choosing and maintaining HPDs refer to the Noise in the workplace – Approved Code of Practice (ACOP).

TRAINING AND EDUCATION

All workers should be trained in the selection, fitting, use, care and maintenance of HPDs.

Health and safety inductions should include an explanation about the risk that removing HPDs can have to an individual’s hearing.

Hearing protection devices must not be used as a substitute for noise control.

During the production, workers’ exposure to noise should be monitored to ensure they are not being exposed to excessive noise.

If noise does exceed exposure limits, the PCBU must put in place a hearing conservation programme and may consider carrying out audiometric testing.

For more information refer to the Noise in the workplace – Approved Code of Practice (ACOP).

Funders should:

In pre-production, production companies (likely to have primary responsibility over health and safety on the production) should:

As producers and production managers have oversight across the production, they should:

Directors should:

Heads of departments should:

They must also ensure all HPDs are manufactured to a recognised Standard and are the correct grade for the noise level encountered

The assistant director/s should:

The health and safety officer should:

Audiometry means the measurement of the hearing threshold level of a person by means of a bilateral pure tone air conduction threshold test.

Excessive noise, for the purpose of this document, is noise7 that is at or above the following levels—

Hearing protector means a device or pair of devices that have been tested to an appropriate national or international standard and classified (or graded) by a suitably equipped and independently audited laboratory with full trace ability to National Standards. Such a device is worn by a person or inserted in the ears of a person to protect that person from exposure to noise.

Impulse noise means noise consisting of a single pressure peak, or a sequence of such peaks, or a single burst with multiple pressure peaks, or a sequence of such bursts.

Noise means any sound which is present in the place of work whether it is wanted or not wanted, and includes sound energy of any frequency, whether or not capable of being perceived by the unaided human ear

Noise-induced hearing loss is hearing loss that occurs due to excessive noise exposure; it can be identified by deterioration in hearing, a loss excessive for age, or a noise pattern discovered during audiometric testing

Health and Safety in Employment Regulations 1995

Occupational Health and Safety Service, Department of Labour (now WorkSafe New Zealand); A Message to Employers on Preventing Hearing Loss

Occupational Health and Safety Service, Department of Labour (now WorkSafe New Zealand); Management of noise in the workplace – Approved Code of Practice (ACOP)

Occupational Health and Safety Service, Department of Labour (now WorkSafe New Zealand); Noise fact sheets 1-6

ScreenSafe is not a hotline for specific Health & Safety issues or concerns, please direct these to your Health & Safety representative or WorkSafe

For more information about any of the initiatives ScreenSafe is working on please speak to your relevant Guild representative or contact info@screensafe.co.nz

© 2016 | Created by Green Chilli Design